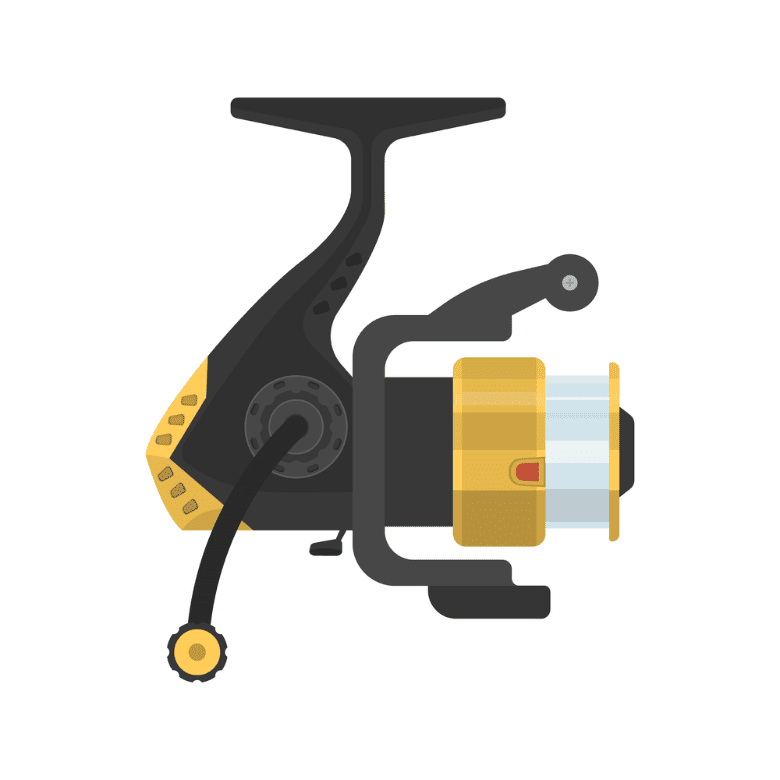

Getting the best out of your spinning reel is made a heck of a lot easier when you understand the critical working reel parts and what they do.

Importantly, it also helps you purchase spinning reels that are appropriate for the intended application.

Knowing every single working part, while helpful, is not really necessary for better fishing results.

Check out the schematics of an average spinning reel, and you will discover a mind-boggling list of bits and parts. Knowing bush and bearing tolerances won’t help you land a tarpon.

Unless you wish to do advanced reel maintenance or major servicing DIY, knowing the full list of parts of a spin reel isn’t really necessary.

Today we’re going to focus on learning the parts you need to understand.

There aren’t that many, and while some parts and functions may appear obvious, you may encounter things you might not have considered.

Let’s check out the critical spinning reel parts in some detail.

Page Contents

What Are the Parts of a Spinning Reel Called?

You should understand 10 spin reel parts, as knowledge of these parts will impact your fishing, reel maintenance, and selection.

Here are the 10 most important parts of a spinning reel:

- Spool

- Bail Arm

- Body

- Side Plate

- Gears

- Rotor

- Drag

- Handle

- Anti-Reverse Switch

- Line Roller

For a good look at all the working parts of a spinning reel, as well as detailed reel maintenance, check out this video below.

1. The Spool

As you are aware, it’s the spool that holds the fishing line. Typically made of lightweight alloys, you can also find some which have graphite spools.

A well-constructed spool delivers balance, which is particularly important for even and consistent line-lay.

Smooth, well-chamfered spool lips enhance casting manners as they reduce friction. Friction will always kill distance and degrade fishing line faster.

The spool lip should always be protected from bumps and scratches, as resulting sharp edges can cause the line to damage and break.

A spinning reel spool doesn’t rotate when cast. It only rotates when a fish is pulling line from the reel during a fight.

While winding, a spin reel spool oscillates, unlike a baitcasting reel. Also, unlike a baitcaster, a spinning reel spool is anchored to the reel through its center.

You may see spools with holes of various shapes on the side. These are called ports and are designed to disperse heat and reduce weight.

While they won’t tell you this, much of the porting is really only for aesthetics.

Line capacity information will always be printed on the sides of spools, helping you rig within reel specifications.

Also Read:

2. The Bail Arm

The bail arm is wire, usually black or chrome, through which the line is threaded. The bail arm is connected to the rotor, which rotates when you wind the handle.

The bail arm holds the line roller, which is the component that guides the line onto the spool. We’ll look at the line roller in detail later.

To cast, you have to flip the bail arm to the open position. This allows line to peel from the spool freely. You will feel a little resistance when you open the bail arm because it is spring-loaded.

Many bail arms close automatically. All you need to do is turn the handle, and the bail arm will close into the winding position.

For other reels, you must close the bail arm manually.

Automatic bail arm springs are often degraded by corrosion, which can also introduce corrosion to other parts. Many anglers prefer manual bail arms for this reason.

While they might look fragile, bail arms can handle quite a bit of hard work.

Look for bail arms that are lightweight yet a little thicker, as they handle impacts a shock force a little better.

3. The Body

The body of the reel houses the gears, pinion, bearings, and bushes. Modern, premium reels are nearly always constructed from machined or cast alloys.

Graphite and steel are more common in more affordable spinning reels.

The optimum specs for a reel is a body that is rigid, strong, sealed, and lightweight. Expect the more expensive reels to have all three of these desirables.

The basic requirement, however, is rigidity.

The forces of fighting fish can make a reel body flex, which can impact the gears and other internals adversely. A rigid body ensures gears remain in perfect mesh.

Gears operating out of mesh perform poorly and wear faster. For that matter, any flex stress on internal components increases wear and reduces the peak working life of the reel.

4. The Side Plate

The side plate sits on the side of the reel body and is connected by screws. It’s basically a point of access for internal repairs and maintenance.

Side plates are usually constructed from the same material as the rest of the body.

The side plate is well known as a place for dirt and water ingress.

Premium reels have sealed sideplates to mitigate water ingress, but even then, the side plate should be regularly inspected for seal and connection to the body.

5. The Gears

When you turn the reel handle, you turn the gears that turn the pinon gear that turns the rotor.

Gears are designed to deliver a certain speed, which is referred to as the gear ratio. A gear ratio is the number of times the rotor will turn per 1 turn of the handle.

Gears are often constructed from cast metals, but machined gears are preferred due to their greater tolerances.

Brass and stainless steel are both common materials for gears, as well as a multitude of alloys.

The gear attributes most desired are strength, tight tolerances, finer, more numerous teeth, while being lightweight and durable at the same time.

6. The Rotor

When you turn the handle, the rotor oscillates and rotates to put line onto the spool.

Rotors are frequently constructed from graphite, including premium reels. Rotors are also constructed from the same material as the body.

Manufacturers place premium focus on constructing a rotor that is lightweight, exceptionally well balanced, and highly rigid.

The lighter, and more balanced the rotor, the more fluid and balanced the crank or wind.

Good rotors are strong, rigid, and very light. Look for a strong connection point to the bail arm.

7. The Drag System

Drag is a collection of washers operated by a screw (knob on the front of the spool, or rear of the body) that allows you to regulate pressure on the spool.

Washers are constructed of an oil-felt or carbon, with some reels containing a combination of both.

The tighter you wind the drag up, the harder it is for the fish to pull line from the spool. Releasing pressure allows the fish to pull line more freely.

Oil-felt washers will dry out and require more maintenance or replacement than carbon washers.

Carbon washers in drag systems are the most desirable since they dissipate heat more quickly and take longer to wear or compress over time.

8. The Handle

Handles are made for cranking, with better handles offering good grip and well-considered ergonomics.

A comfortable knob is advisable but not always guaranteed – even on premium models. Comfort is a personal preference, so it is best to feel a reel before you purchase.

Handles that are constructed from machined alloy are usually the best.

The better models feature handles that screw into the body instead of retaining bolts on the opposite side.

Good handles are well connected to the body and have no movement beyond rotational movement. Many handles can be collapsed for easy transportation.

9. Anti-Reverse Switch

Thankfully, Anti-Reverse switches are becoming a thing of the past.

Spinning reels have an anti-reverse system, so you stop the reel’s ability to wind backward, and stop the spool from turning backward – an important feature for solid striking and line management.

Anti-reverse is managed by a dedicated bearing.

However, it has been common to have a switch, usually on the rear of the body, that allows you to disengage anti-reverse.

In 40 years of fishing, I’ve found absolutely no use for it, and it’s more of an appendix on a modern spinning reel.

Anti-Reverse switches are often the first part to break on a reel. Look for reels that don’t have this particular feature.

10. Line Roller

The line roller is an integral feature of the bail arm. Its sole purpose is to guide fishing line onto the spool.

Premium reels utilize a bearing to reduce friction, whereas most reels have a fixed, highly polished metal cylinder, often shaped to channel line to the center.

Line rollers with a dedicated bearing are usually seen on more expensive reels, and they are a helpful feature.

If you’re looking for reels at more affordable prices, look for line rollers that minimize points at which line can catch.

Most line rollers work trouble-free. It’s rare you will find a roller that gives any trouble from any price point. Keep an eye on corrosion or burring.

Your line roller should remain as smooth as possible.

What to Look for in a Good Spinning Reel?

Here is a list of things to look for when purchasing a good spinning reel in order of priority.

- It’s in your budget

- Its specifications suit your fishing application. Drag, spool capacity, size of the reel, and strength.

- It’s rigid

- Quality construction materials

- Quality construction

- Durability

- Lightweight, alloy body

- Bearing count. 4 or more, depending on price

- Features such as bearing sealing and body sealing

- Aesthetics

If you want to see 5 of the best fishing reels on the market then click here.

What Gear Ratio Should You Look For?

Ultimately, the gear ratio is not an important feature for the average angler. But keener anglers, particularly lure anglers, will find gear ratios relatively important.

The gear ratio depends on target, style, and geography. For working heavy fish, 4.5 to 5.5 is a good start; the slow speed is also ideal for cranking and swimbaits.

For rapid retrieval, you will need faster ratios.

If you’re working metal slices of stick baits, everything over 6.5 is cool. However, this speed is probably a great all-rounder for most types of fishing.

Frequently Asked Questions

Is A Baitcasting Reel or Spinning Reel Better?

This choice comes down to personal preference. The spinning reel is by far the easiest reel type of all, so recommended for most anglers.

I recommend proficiency with both baitcaster and spinning reels.

Baitcasters will take a little longer to master, but it’s worth it. The truth is, neither reel is better. They’re just different.

What is the Bail on a Spinning Reel?

Check the section above on the bail arm and its purpose.

What’s the Best Spinning Reel?

Asking, “What’s the Best Spinning Reel?” Is not the best question. There are simply too many answers, and they’re usually subjective.

Rephrase the question to what’s the best spinning reel for this price and the application. You’ll still get plenty of different answers.

For an example of the best top-shelf models consider Daiwa Saltiga, The Shimano Stella, and the Van Staal. You’ll need to sit down when you hear the price, however.

The Spin Reel Parts Wrap Up

Every experienced angler will advise you to get to know your kit and equipment. Knowing what the critical parts do on a spinning reel is the absolute basic or minimum.

Knowing parts allows you to maximize performance, select appropriate reels for particular applications, and, importantly, purchase quality spin reels.

Having a working knowledge of the parts also gives you the ability to assess problems and malfunctions and to speak with a reel technician.

In short, knowing your spinning reel parts will boost your catch, save you time and maybe money, and increase your fishing skills generally.

Sharing is caring!